James

As far as I am concerned, adding or taking away shims from the cold start thermostat and the barometric compensator are a half-@$$ way to adjust the pump. The main rack screw on a 230sl is more difficult to get at than the 250 and 280 pumps, but it adjusts in the same manner, The biggest problem is usually getting out the slot head acess plug, this behind and below the cold start solenoid. Often it takes a 3/8 impact with a screw driver socket to get it loose.

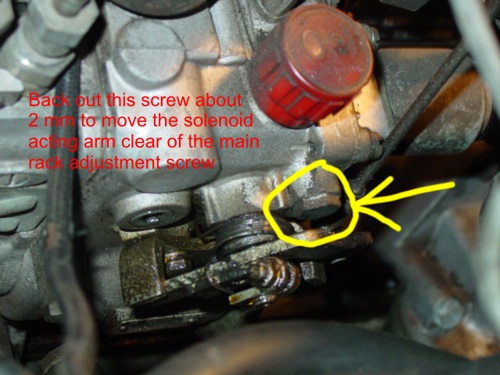

Next problem on a 230Sl pump is that the starting solenoid's acting arm inside the pump is blocking access to the adjustment screw head, There is a 14mm bolt head near the return spring of the throttle linkage arm

This screw head is the fulcrum that the arm pivots on. backing out this screw will move the arm clear of the adjusting screw, Turning the screw more than the the 2 or 3 mm needed to get clearance for your screwdriver will cause the arm to fall off the pivot, so be careful not to turn the screw too far.

Now a screw driver can be inserted in the main rack screw, one click here is a much larger adjustment than on the idle thumb screw and it works in the opposite direction,

Any time the motor is restarted the pivot bolt needs to be returned to its original position, This is a lot of back and forth work getting the mixture adjusted this way, but I think you will get much better results.

Good Luck

(BTW) this procedure is for 6.3 pumps too

Al Lieffring

66 230Sl

Jones'n for a new gas tank