George .... I am not sure that I understand all of your questions but I'll try.

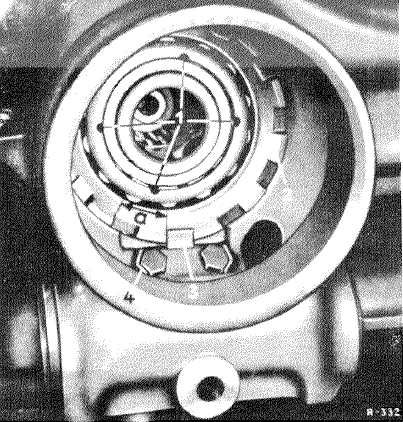

I assume that the carrier taper bearing adjustment nut is the nut you are asking about (the picture is from a 190SL manual; I assume that yours is the same). This is the image of the right hand nut. It requires a special tool to tighten. Tightening this nut puts pre-load on the bearings. 4mkg or 25 ft/lb will set the correct pre-load. By adjusting the carrier bearing adjustment nuts on both sides, you can move the ring gear in or out to adjust the backlash. After getting the desired backlash, torque one adjustment nut and recheck the backlash.

The correct backlash is so that you can just fee the backlash (or gap between the gears) by turning the pinion.

If you need the special wrenches, the 190SL Group will be selling them in a few days (email me, 190SLJim@cox.net, and I'll notify you as soon as I receive them for my stock).